Mechanical Wear Protection

- Superior bi-metallic mechanical wear protection

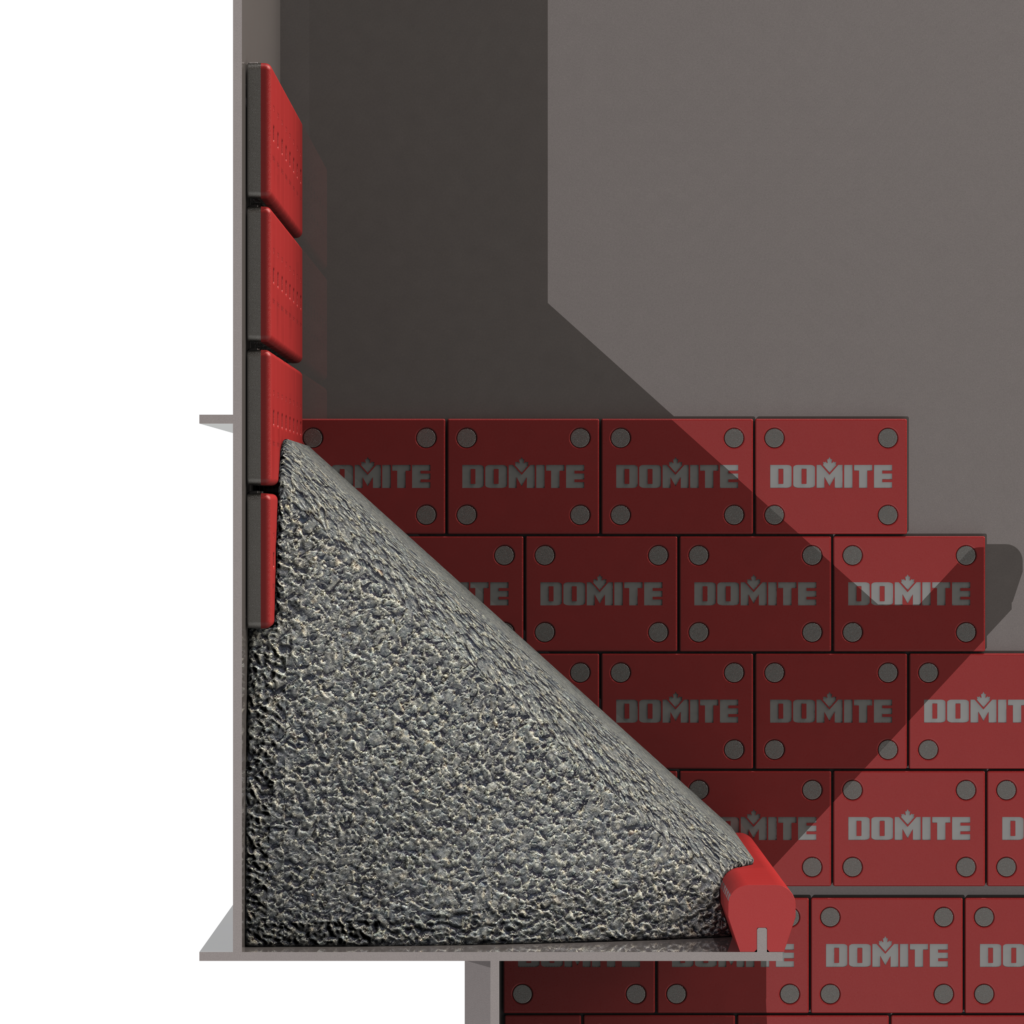

- The Domite wear cap features a 725+ brinell chrome white iron wear face (vs competitors 320-400 BHN) for maximum abrasion resistance, alloy steel backer provides impact resistance!

- Alloy rich – chrome, moly & tungsten primary carbides. Extends life 9 x from AR450

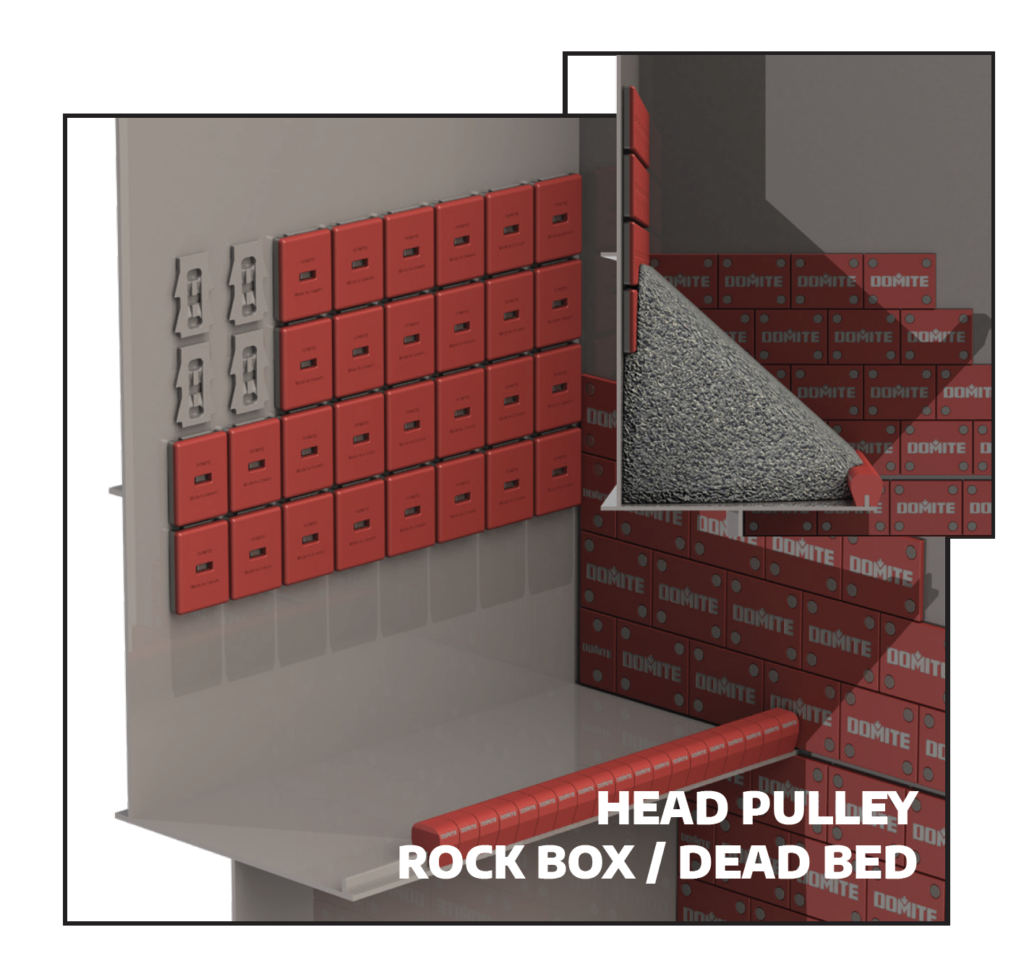

- Quick & easy installation. Once the base plate is welded in place simply slide the Domite wear cap over top, no hot-works, no bolting

- Safer & easier to change than conventional weld / bolt in liners, greatly reducing maintenance change out & downtime in confined spaces.

- Facilitates one sided attachment, no access to the back required.

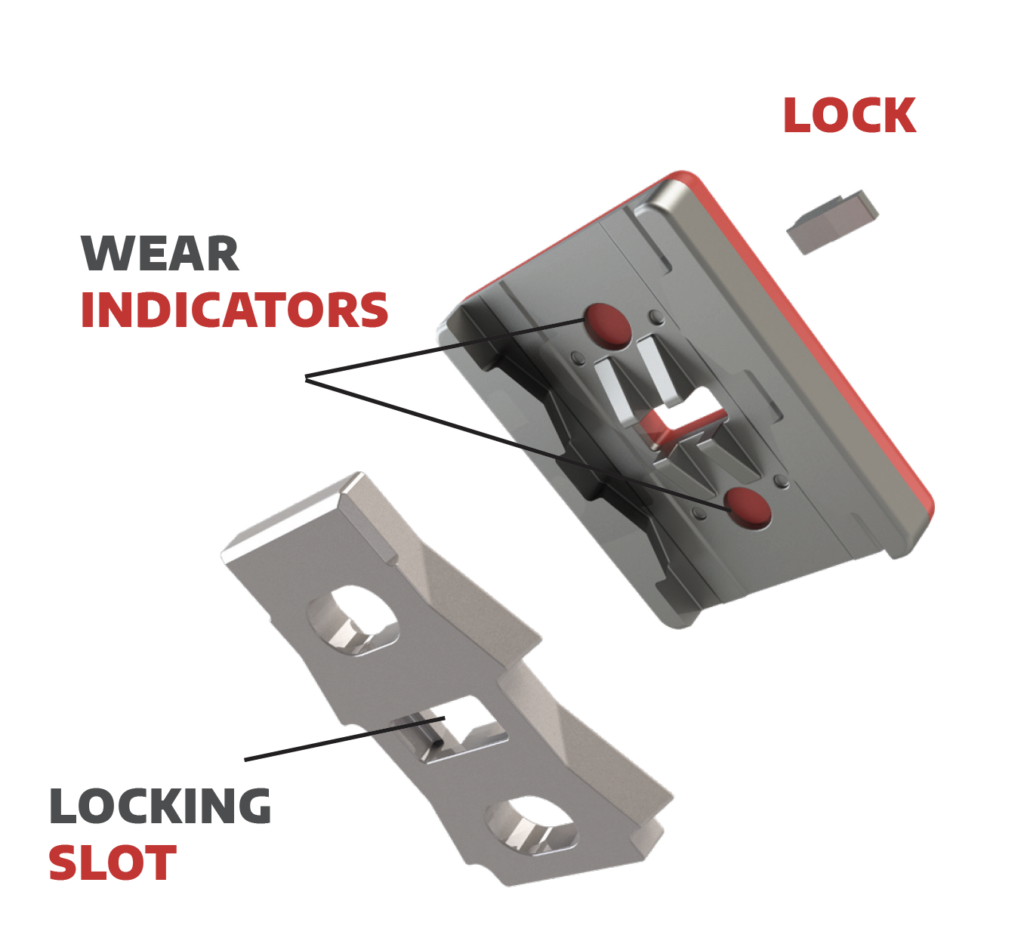

- The runner includes 2 x wear indicators, when the wear material is worn down and an indicator

- Visible, it will alert maintenance personnel its time to invert or change the cap out.

- Engineered internal tapers hold the wear cap to the base plate.

- The re-usable base plate is protected from wear.

- Gravity held and lockable options available.

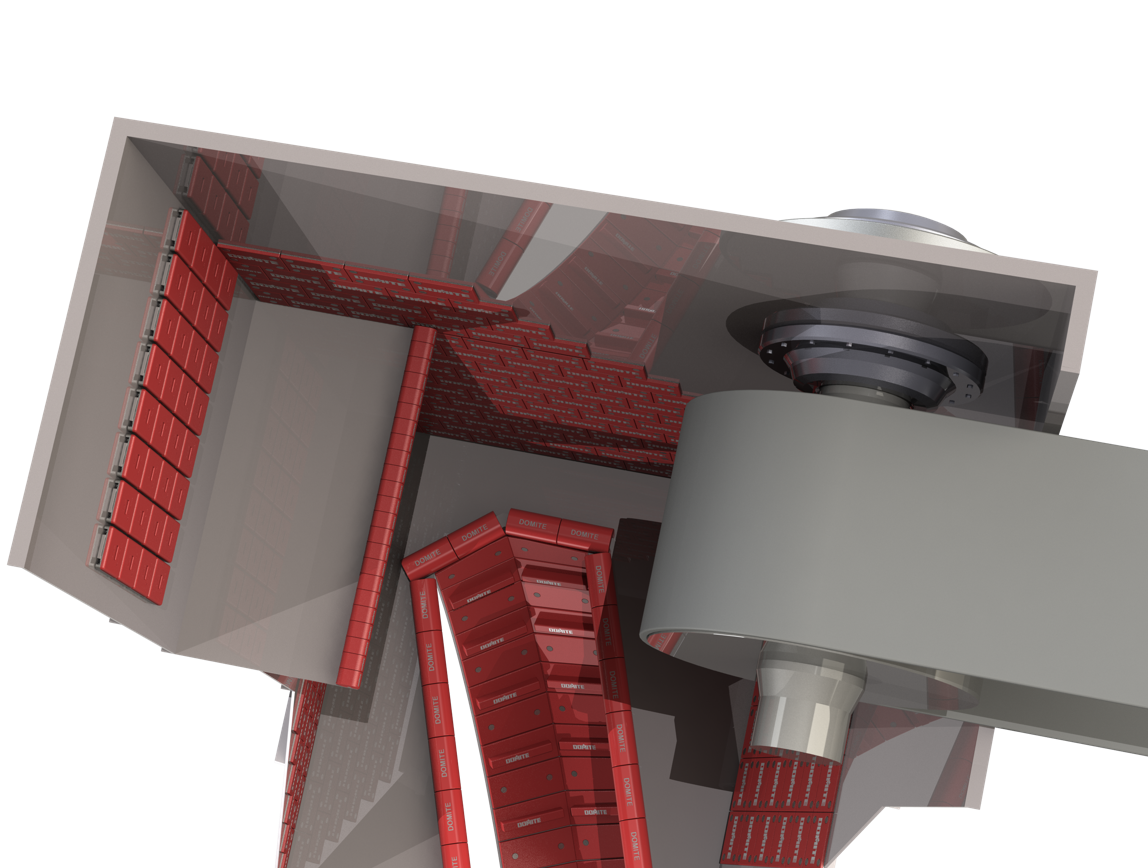

Transfer point

One sided attachment

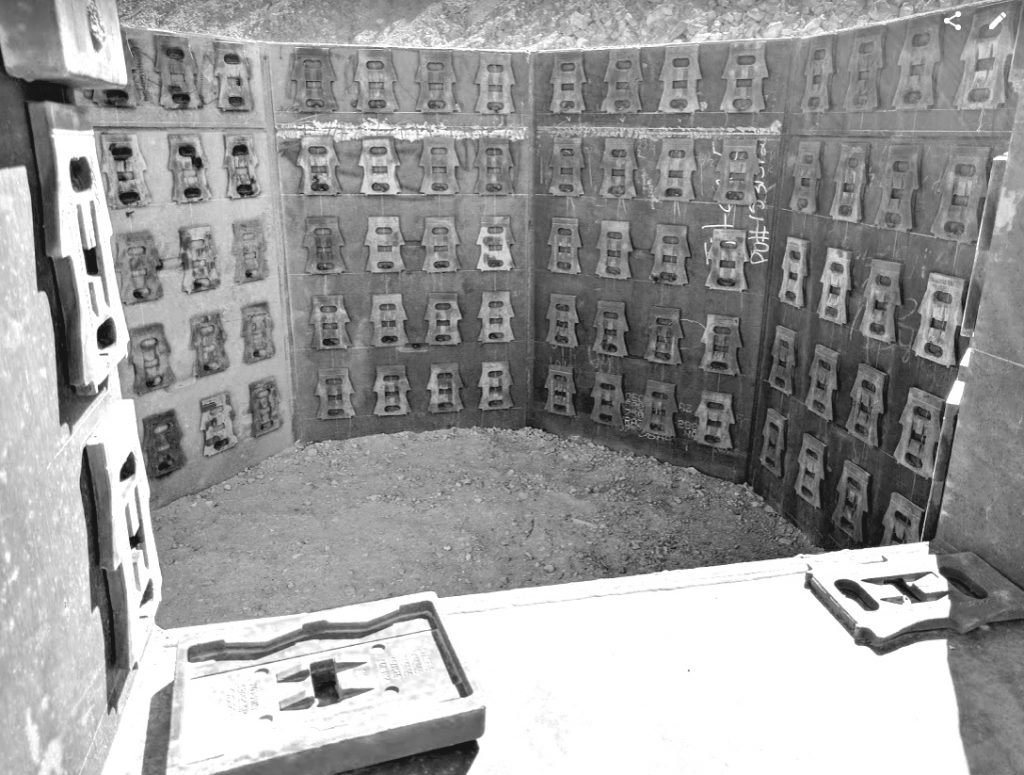

Gyratory Octogen

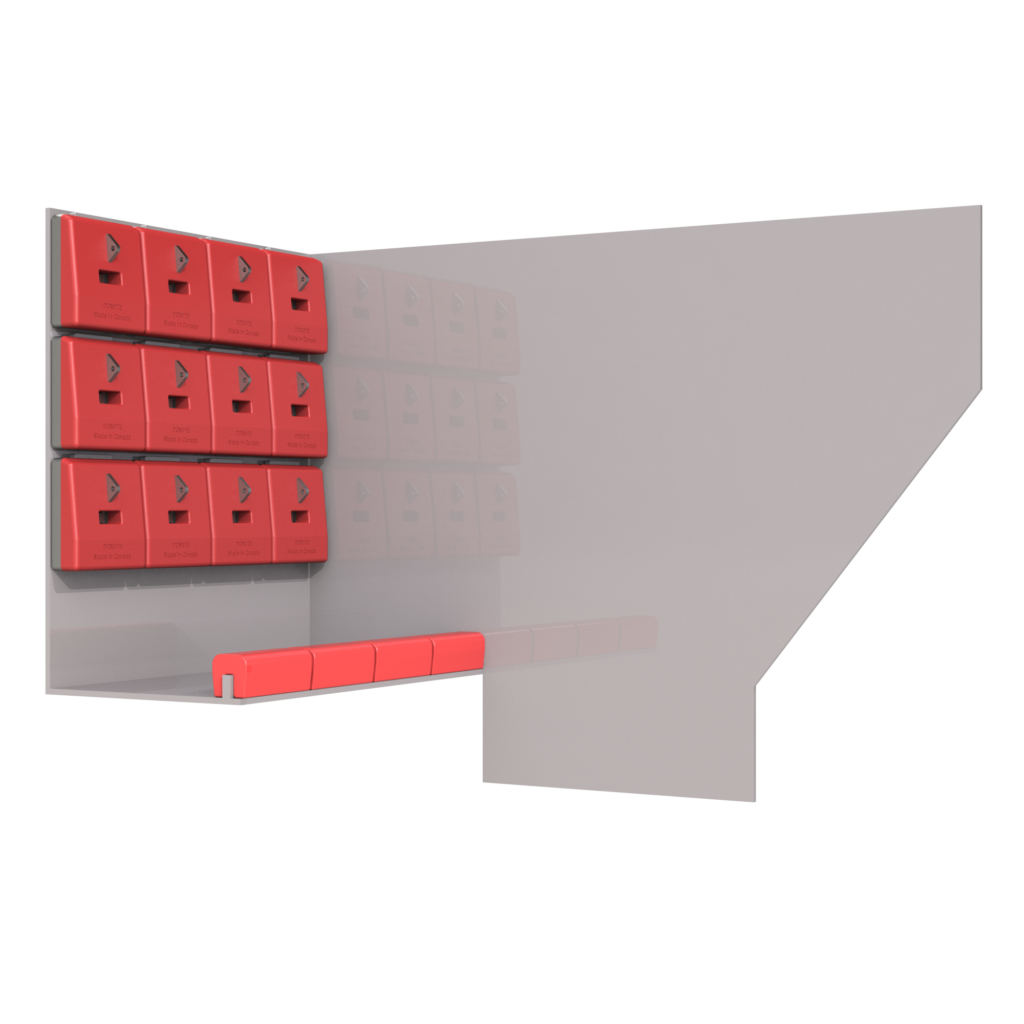

Different Styles Allows for Use in Multiple Applications

Both gravity held hanging and locking options available.

Hanging

Locking

Skirting

High Wear Hanging

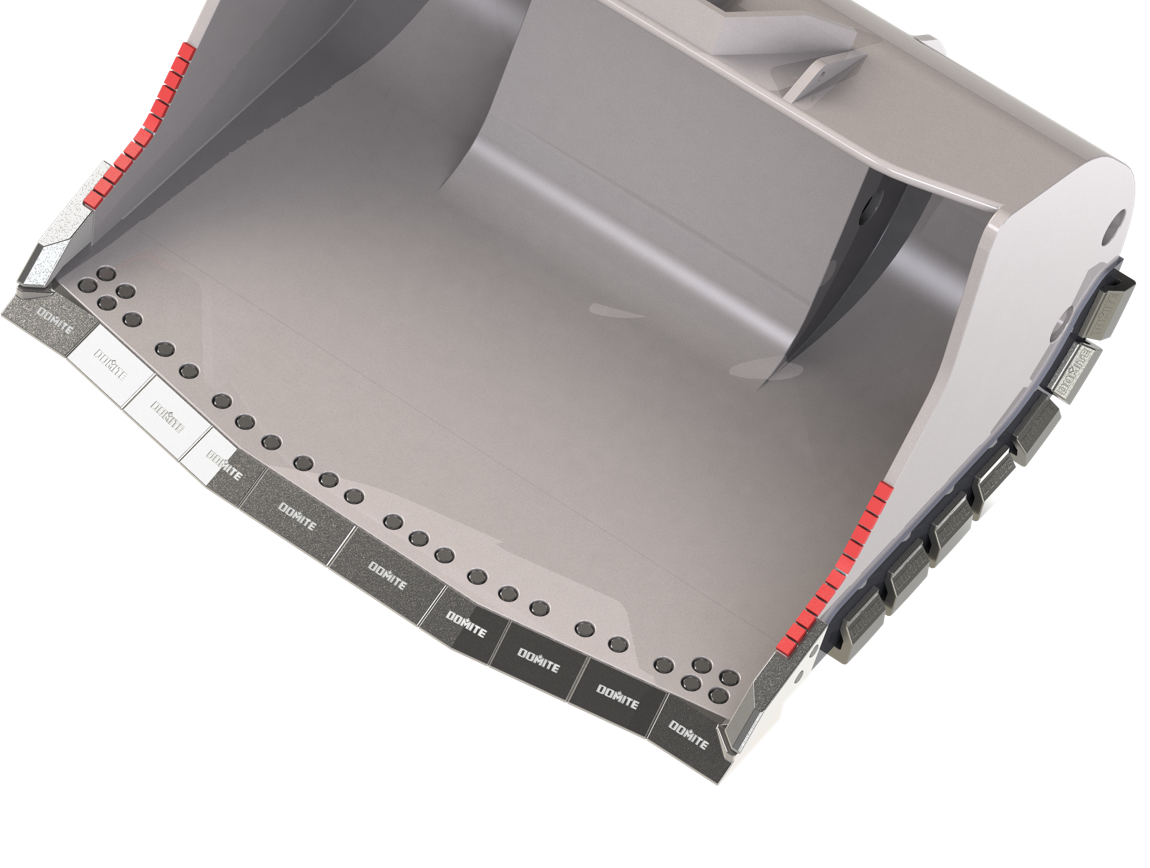

Mobile

DOMITE® creates custom shapes and sizes specifically designed for your application.

Custom Parts