Domite Laminated Plate differ from overlays that have a 1 : 1 ratio of wear resistant material to mild steel, Domite® can have a proportionally thicker ratio of wear-resistant material, yielding longer service life.

Consideration must be given to the criteria of producing a solid cast component resulting in the following guidelines:

- General Thickness Ratio’s of 3:1 Domite® CWI to Mild Steel

- Continuous Elevated Temperatures of 425 C (800 F) and Frigid Temperatures of -50 C(-120 F)

- Thickness Ranges of 3/6” (5 mm) – 4” plus (100 mm plus) for the Domite® CWI

- Mild Steel Backing Plate Thickness of 1/8” (3 mm) – 1” plus (25 mm plus)

- Individual sizes of c. ~ 16” (405 mm) x 16” (405 mm)

Please note that these are guidelines only and combinations can be altered to suit your application.

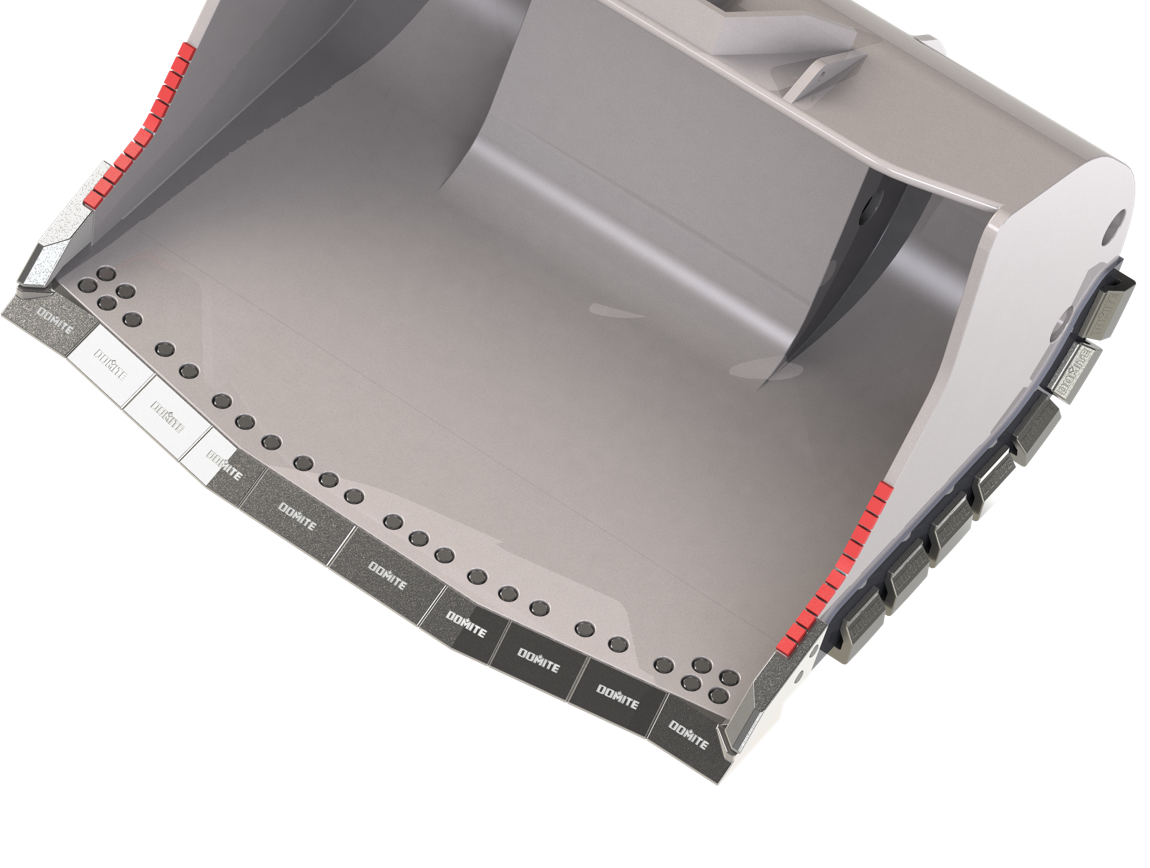

Non-traditional and irregular shapes (triangles, tapers, cones, parallelograms, etc.) can be produced providing the dimensional limitations for good castability are upheld.

In the case of irregular shapes or contoured surfaces, a flat back is necessary for initial bonding but can be overcome in final design. With years of experience simply speak with one of our sales team members for options and solutions. Virtually any surface and application can be covered using proper design and innovative techniques.

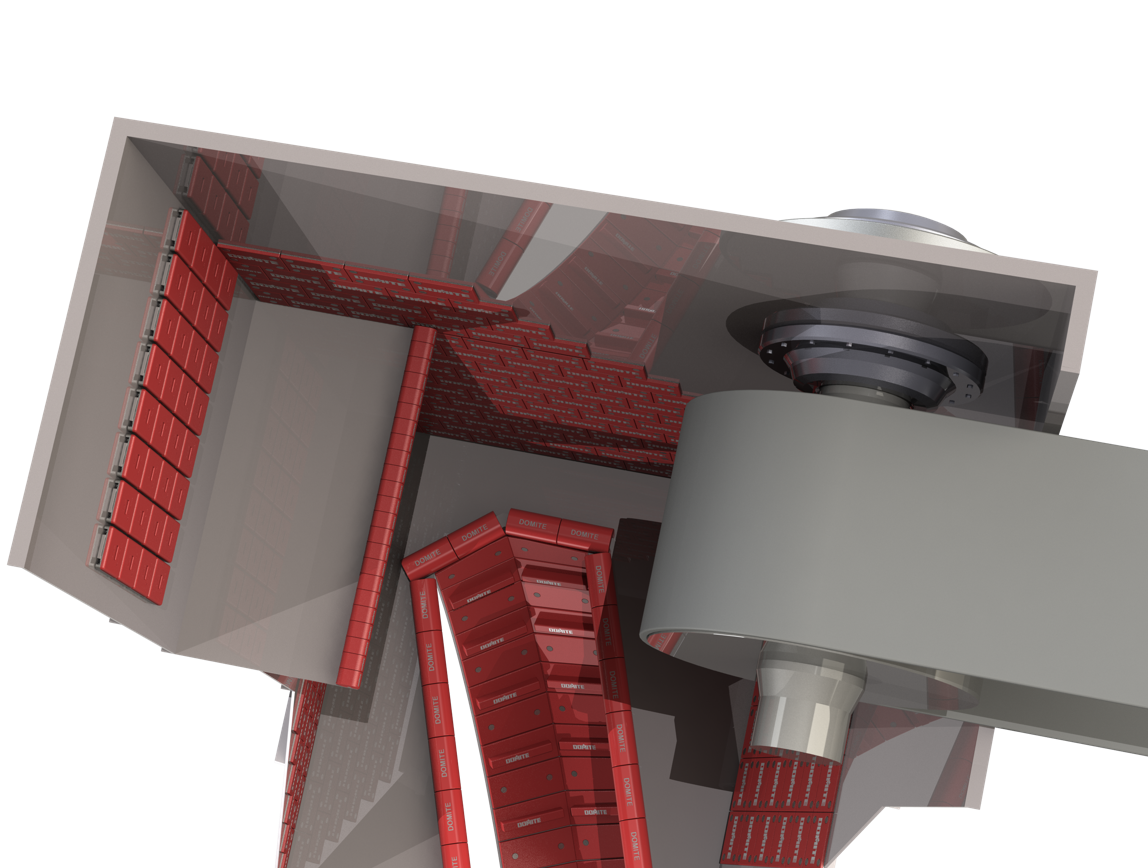

For example: To cover large areas previously protected by insufficient AR plate multiple Domite® plates are arranged in a modular fashion and back welded or bolted onto the fabricated structure or wall covering the desired area.