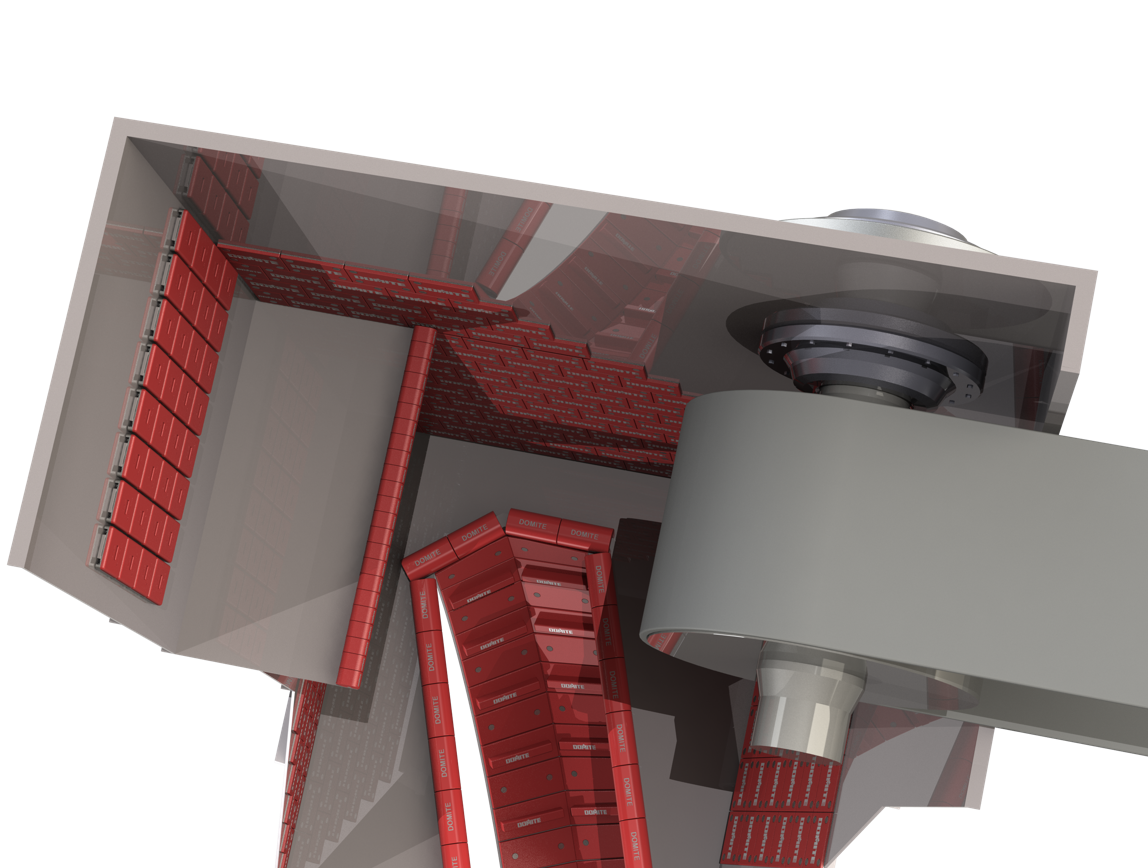

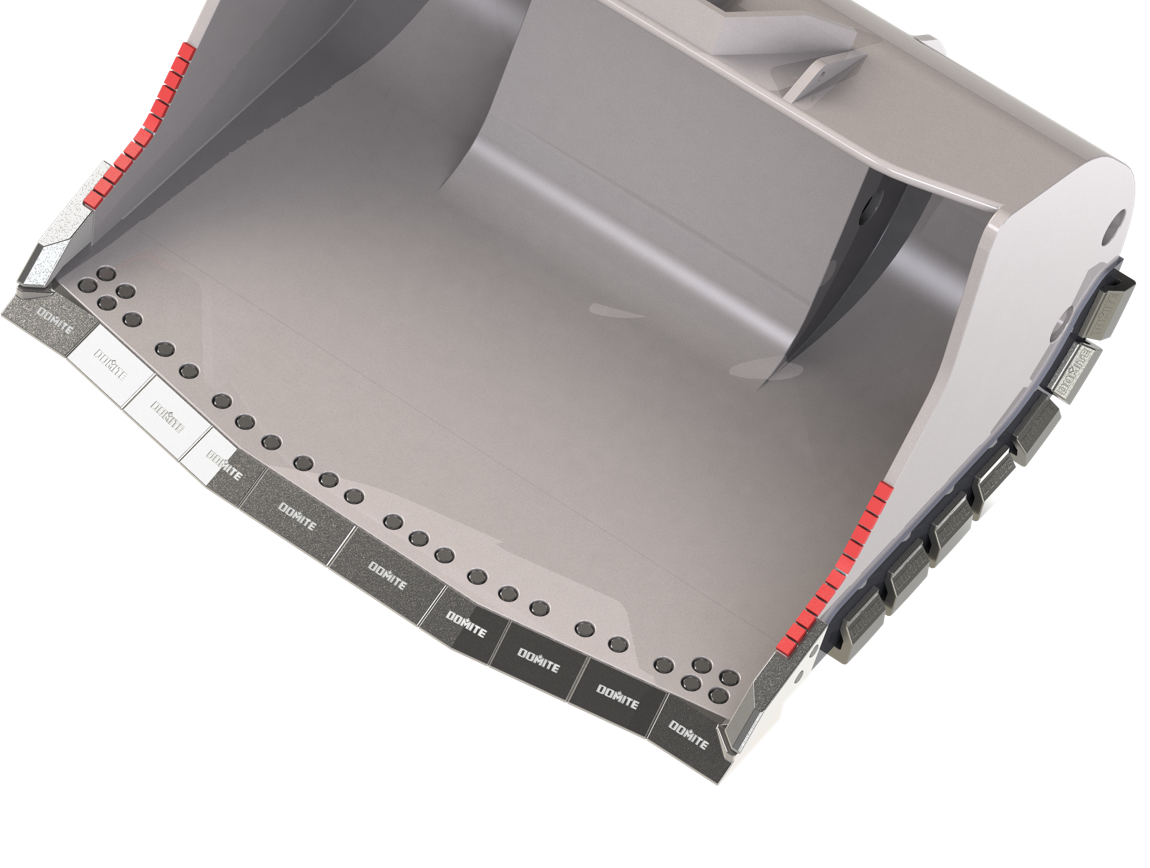

DOMITE alloys are proven in extreme applications since 1967. Proprietary & enhanced for optimum application performance. Our ferrous foundry is capable of casting the following alloys for.

Wear Resistance

Domite CM – an alloyed high carbon chromium – molybdenum martensitic white iron. Although the exact chemistry is proprietary, it has excellent abrasion resistant properties far exceeding the industry standard. This alloy is often diffusion bonded to a mild steel backing plate for improved impact and attachment options. Responsive to heat-treatment Domite can be maximum hardened.

Domite PLUS – hardness and abrasion resistance of a material are mainly determined by the carbide formation which provides the wear resistance for the material. Domite PLUS was designed to achieve a balanced and optimum formation of a variety of carbides to pro¬vide the maximum abrasion resistance.

The abrasive wear resistance of white irons is strongly affected by carbide type, size, orientation and mor¬phology.

Domite Chrome – increased levels of chro¬mium and alloying agents produces a tougher metal that shows greater impact resistance while retaining abrasion resistance. This material is a good selection for casting only applica¬tion where bonding is not applicable

Domite High Chrome – Maximum levels of chrome provide corrosion resistance along with primary chromium carbide formation providing abrasion resistance. A tighter control of carbide size and increase matrix stabilizers improve casting toughness against impact which is good for wet and slurry application.

Heat Resistance

These heat-resistant alloys contain at least 12% chromium and are capable of maintaining their mechanical properties at temperatures above 1200 F. These are high alloy content steels composed principally of nickel, chromium, iron and other additives. They are designed to have good surface stability in various atmospheres at high temperatures and have sufficient mechanical strength and ductility at high temperature.

Corrosion Resistance

Corrosion-resistant alloys are often referred to as stainless steels and are designed to perform in a large variety of corrosive environments. They are composed principally of nickel, chromium, iron and other additives. Castings in this alloy offer the unique ability to resist chemical liquid and gas degradation.

Alloy Steels

This wide range of alloys covers mild to medium strength carbon steels along with high strength steels for more structural applications. Very responsive to heat-treatment these manganese, silicon, nickel, chromium, molybdenum, vanadium and other additive alloys allow for a range of hardness values with high mechanical properties.