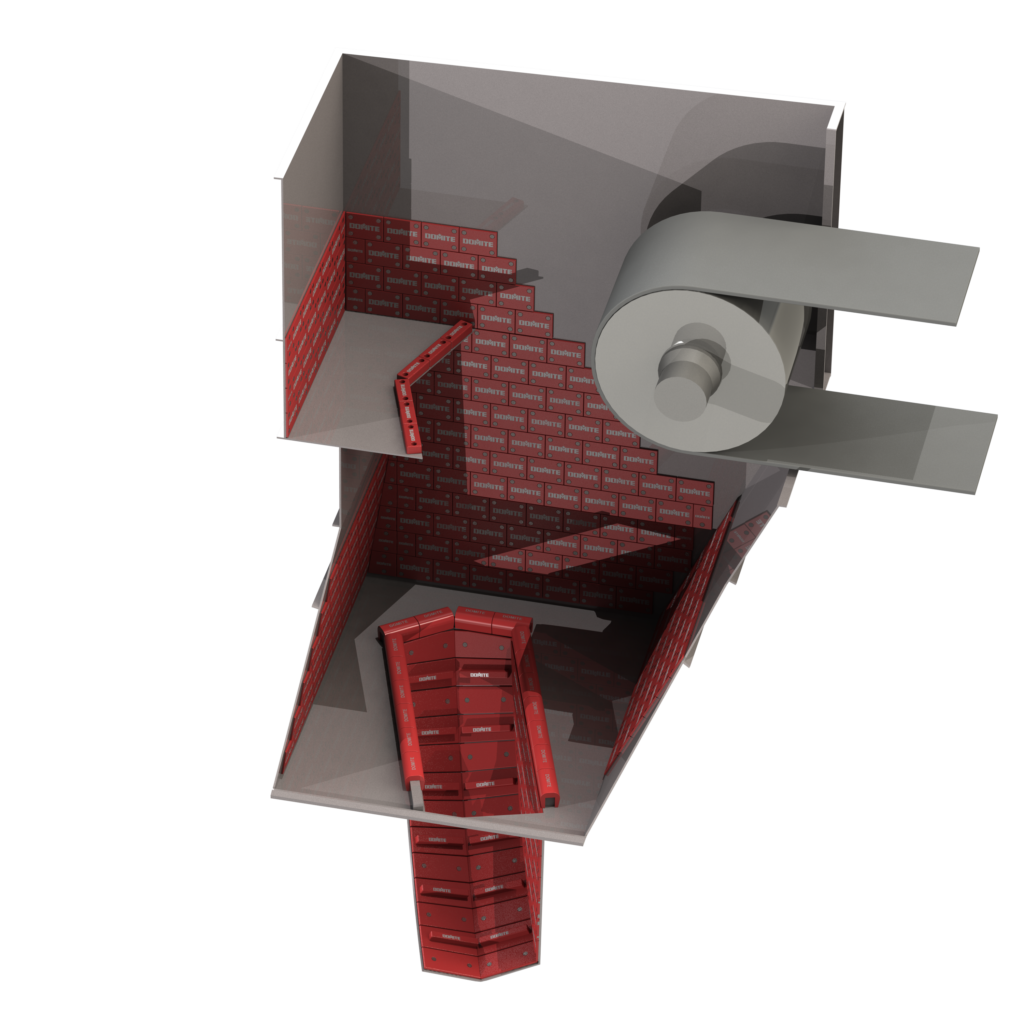

As processing circuits adapt through the different stages of mine, different demands are put on conveyor transfer points. Weather it be increasing through put, ore size variations, ore characteristics (sticky vs hard) or access limitations. Choosing the right products for your transfer points is critically important to the efficiency and productivity of circuit. These include functionality, ease of maintenance, belt loading and tracking, and wear reduction.

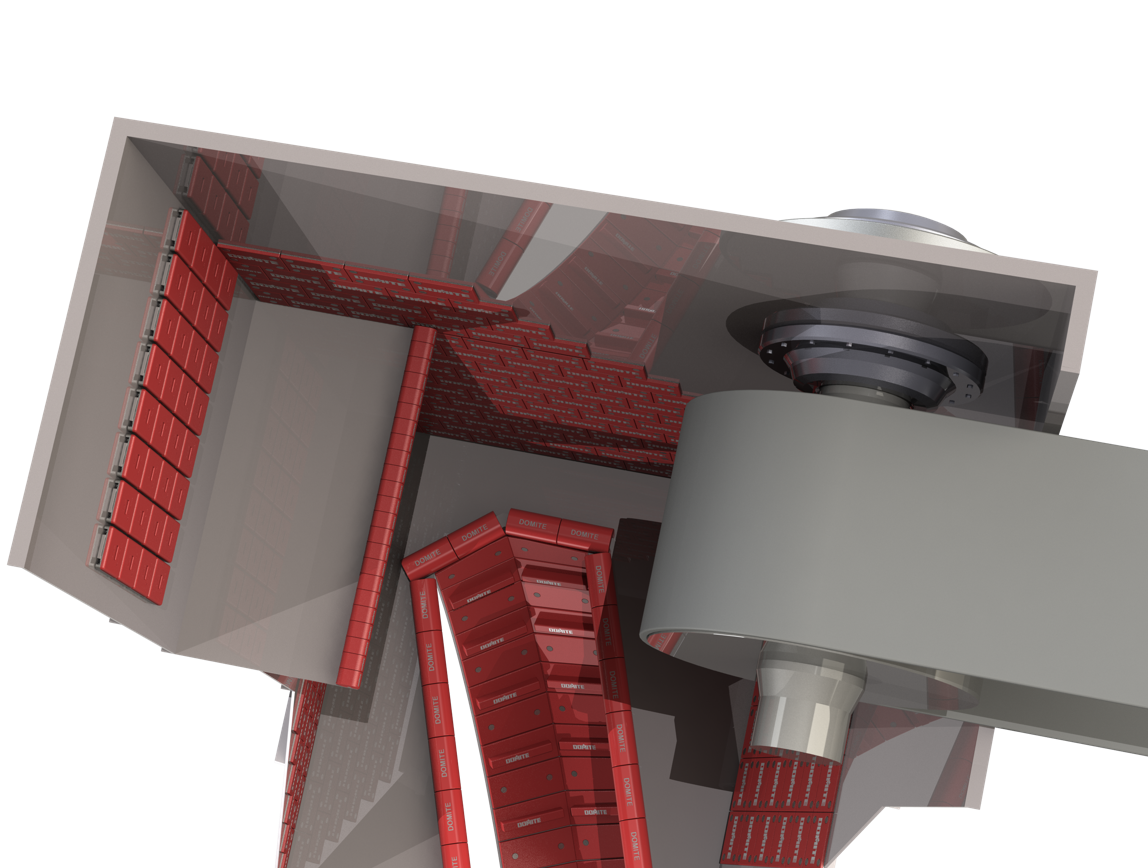

Domite have a range of proven alloys and products to resist extreme impact and abrasion to suit the challenging demands to help control dust emissions, material spillage, belt wear along the skirt lines and rapid skirt liner wear resulting in controlled material flow, a safer environment and lower cost of ownership.

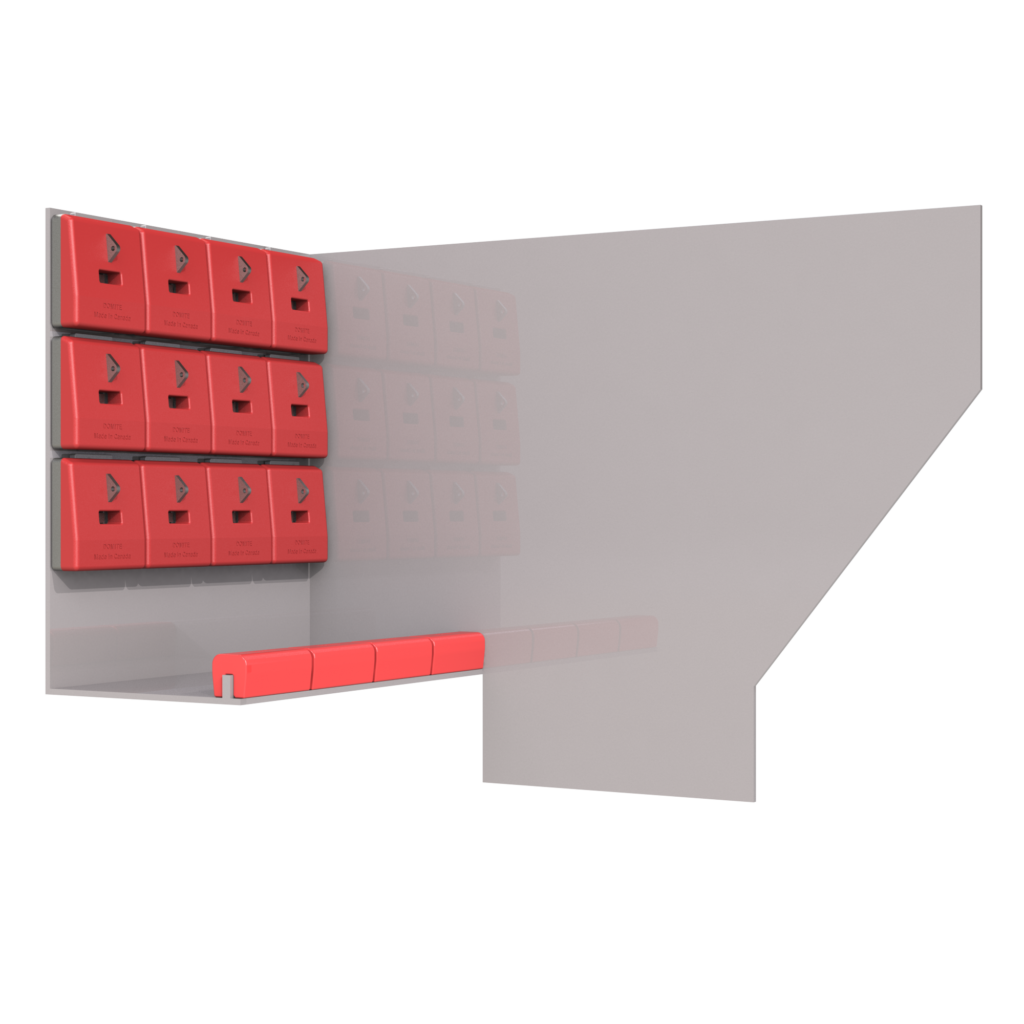

Mechanical options such as the Domite Grav Lock eliminate hot works in confined spaces are light and easy to handle when compared to conventional plate liners. They also allow you to change targeted areas if not all areas of the wall are showing wear, not to mention are incredibly quick to change and done require access to the back.

Bolt in and weld in liners are also available in a range of sizes and thicknesses wether its a new build or retro fit.

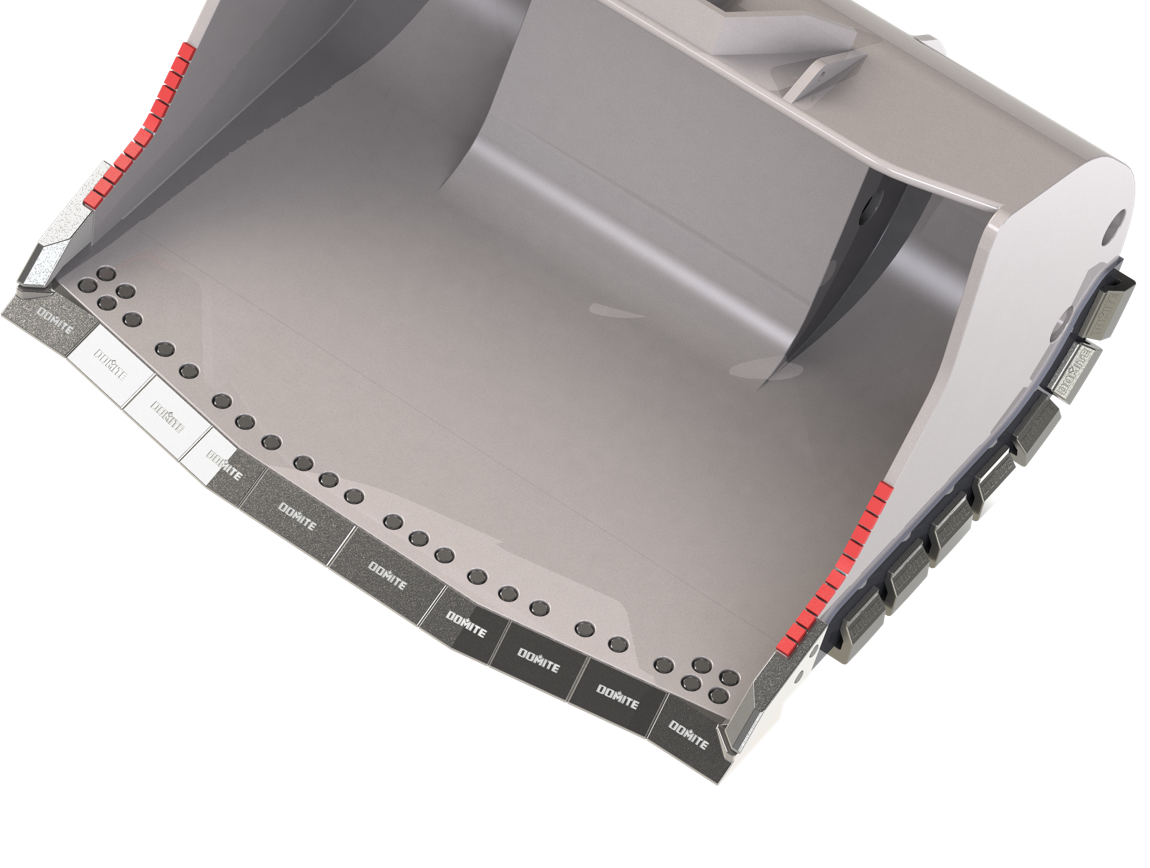

Lip liners

We offer a range of lip liners for the edge of the rock box, weather it be

- Bolt in, such as Micro Ledges, cast lip liners

- Loaf liners that sit on a rail and offer quick change out and maximum protection

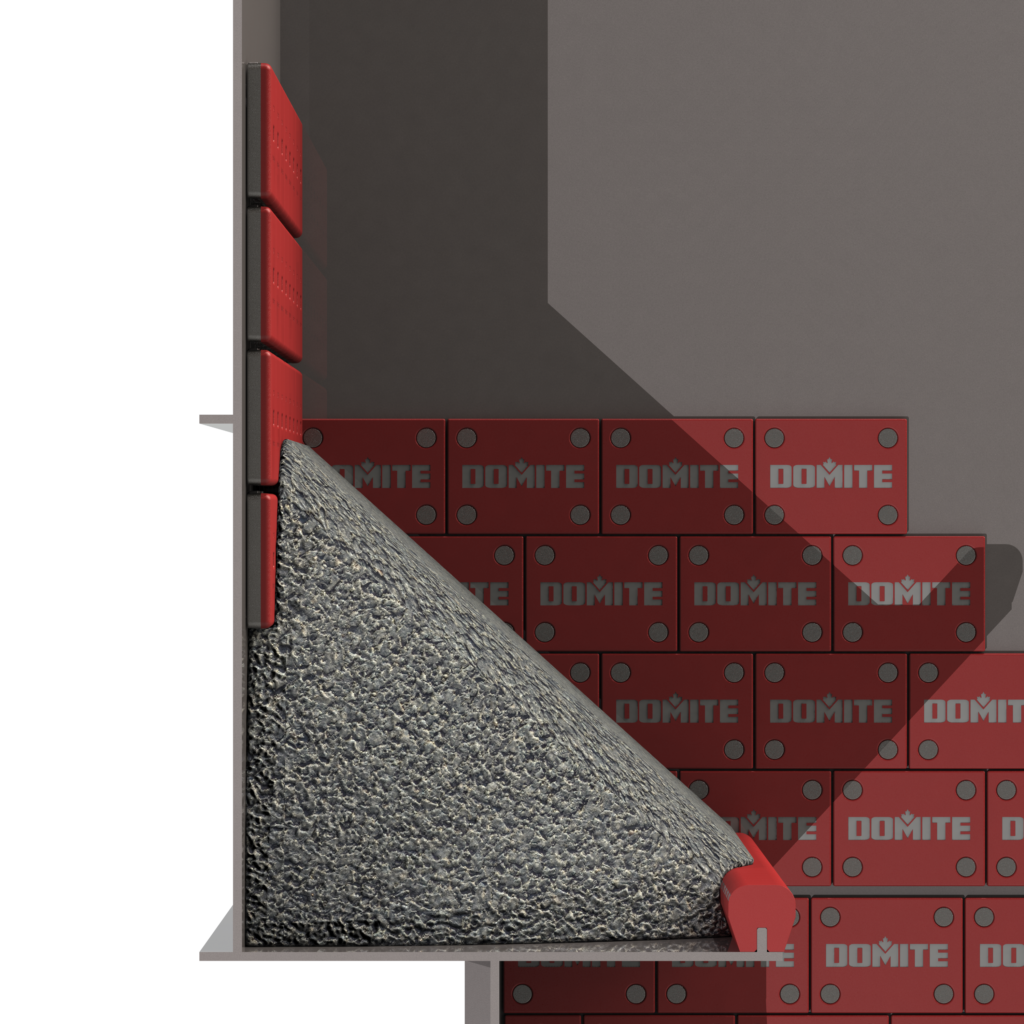

Alternatively we have our transfer point liners which create a dead bed of material, these liners are the medium that hold a bed of material in place so you are getting ore on ore wear vs wearing on a liner resulting in substantially longer life.

Related Products

- Loaf liners

- Lip liners

- Rock box liners

- Grav Lock

- Micro ledge