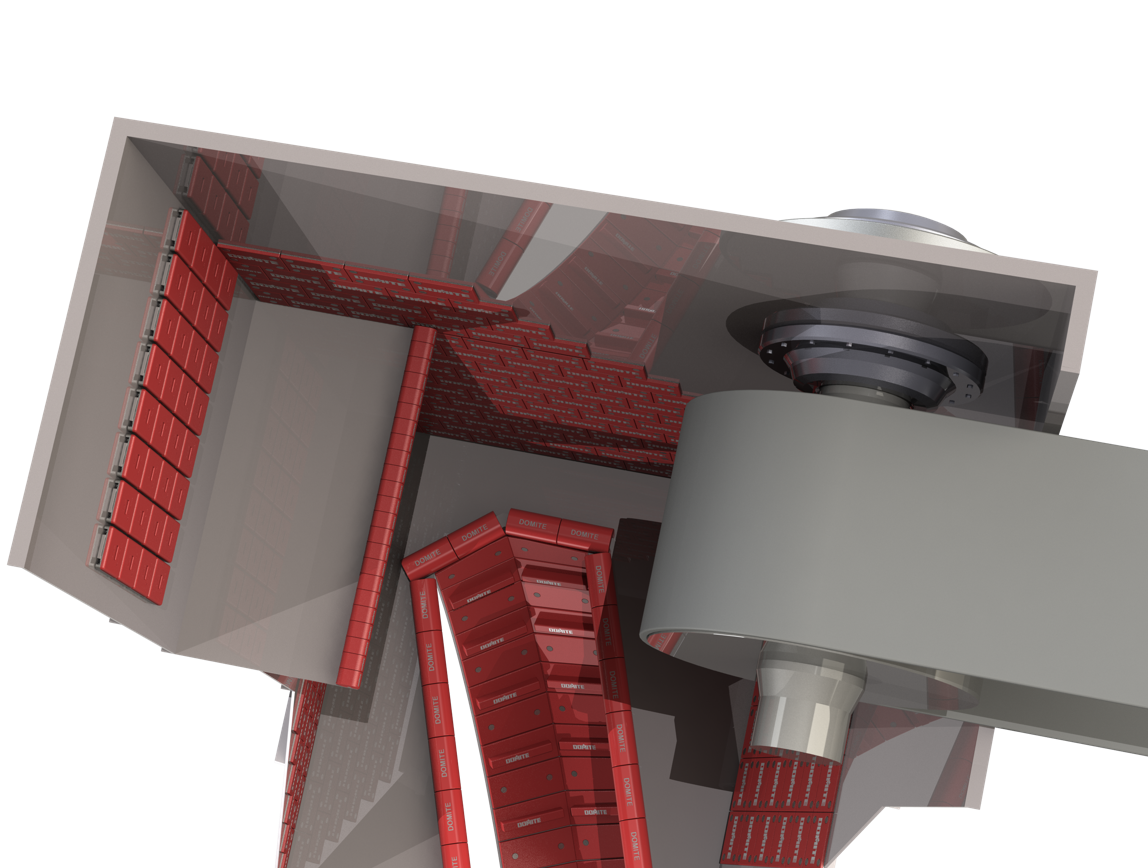

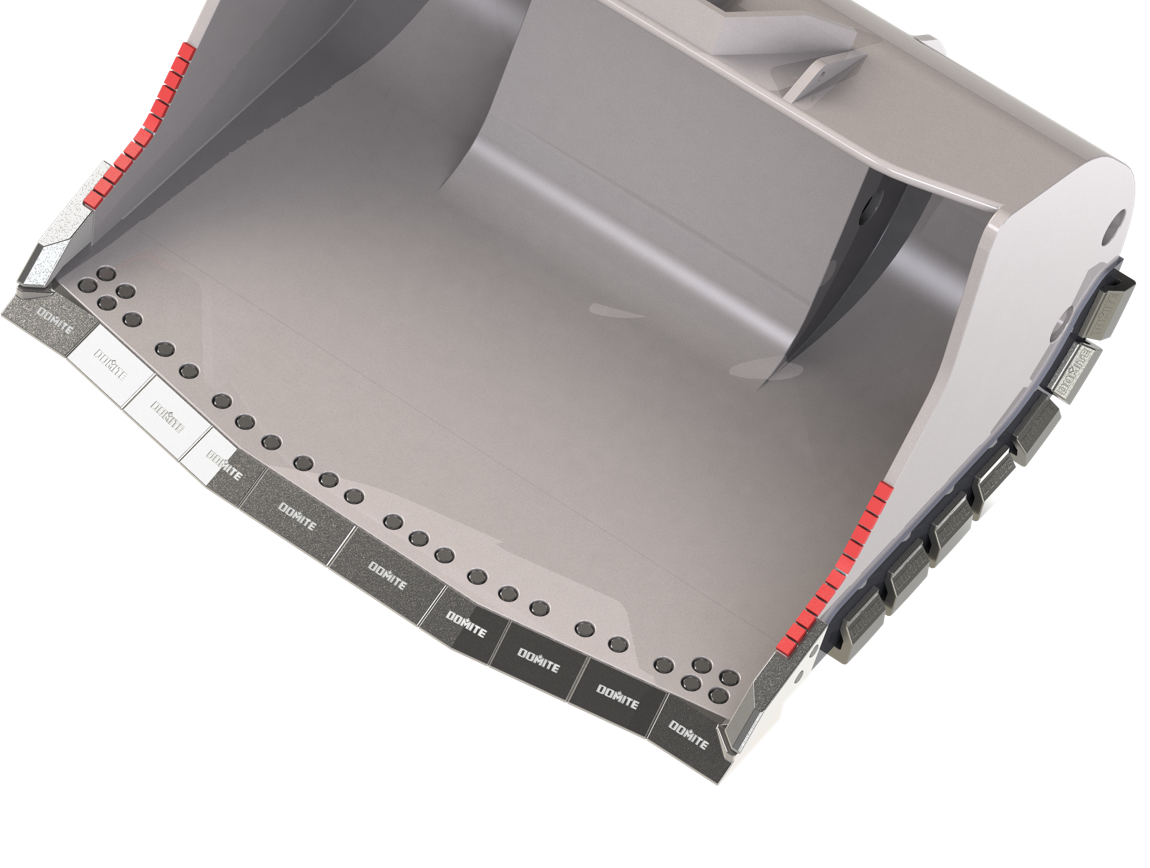

There are a range of options available to attach Domite wear products, historically this has been via welding, bolting, studding or casting a backer plate that fits on a mounting plate.

Industry-first, Domite Bolts reduce premature wear around the bolt hole providing longer liner life.

Through time in the field, and customer consultation Domite Wear Technology have come up with the solution of casting a Domite wear cap for the top of a bolt. Customers often told us they experienced channelling / dishing & erasing in and around the bolt hole of liners thus causing & leading to premature wear & replacement of

the liner stock.

To alleviate this, we custom cast a 725 BHN Domite cap & bond this to the bolt head. This Domite capped bolt fits into a standard corresponding cast hole in the liner.

Using Domite capped bolts will remove interruptions or holes in the wear face of the liner, this will virtually eliminate any wear around bolt holes providing longer liner life.

Traditional style bolt in hole – Left Domite Bolt – Right

Examples of erasing/channelling caused by the bolt holes in the liner, eliminated using Domite Bolts

Typical Thickness Combinations

| OAT | Domite | Steel | Casting Thickness | Domite Bolt Part # | Domite Bolt Thickness |

|---|---|---|---|---|---|

| 25mm [1″] | 19mm [3/4″] | 6mm [1/4″] | 19mm [3/4″] | D10DB | 10mm [3/8″] |

| 32mm [1 1/4″] | 25mm [1″] | 6mm [1/4″] | 25mm [1″] | D16DB | 16mm [5/8″] |

| 38mm [1 1/2″] | 25mm [1″] | 13mm [1/2″] | 25mm [1″] | D16DB | 16mm [5/8″] |

| 38mm [1 1/2″] | 29mm [1 1/8″] | 10mm [3/8″] | 29mm [1 1/8″] | D20DB | 20mm [3/4″] |

| 51mm [2″] | 38mm [1 1/2″] | 13mm [1/2″] | 38mm [1 1/2″] | D29DB | 29mm [1 1/8″] |

| 51mm [2″] | 41mm [1 5/8″] | 10mm [3/8″] | 38mm [1 1/2″] | D29DB | 29mm [1 1/8″] |

| 76mm [3″] | 67mm [2 5/8″] | 10mm [3/8″] | 67mm [2 5/8″] | D56DB | 56mm [2 1/4″] |

| 76mm [3″] | 64mm [2 1/2″] | 13mm [1/2″] | 64mm [2 1/2″] | D56DB | 56mm [2 1/4″] |