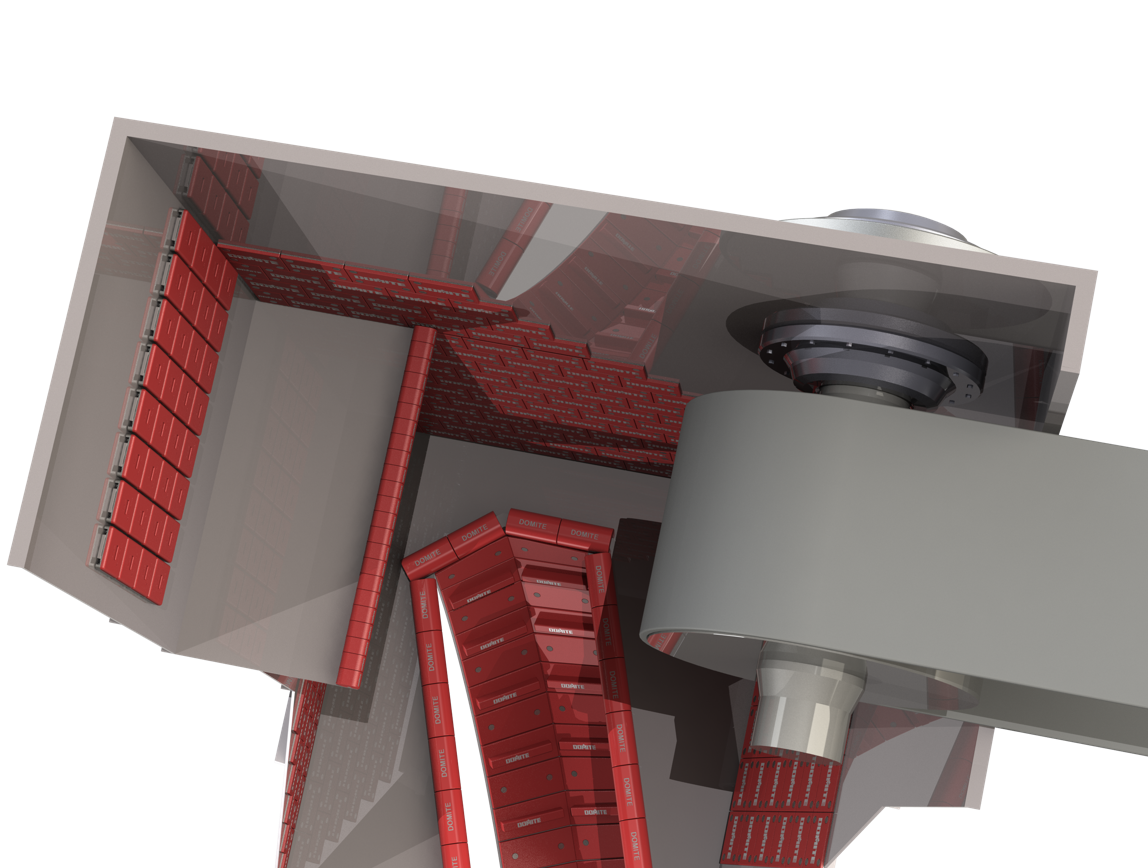

Domite have an advanced knowledge and experience relining underground loadout chutes. Domite’s superior impact and abrasion liners make them the ideal candidate for these often confined space environments with restricted access. Our materials encourage material flow efficiently and safely when conveying various materials. Investing in Domite liners will lower your total cost of ownership, reduce man hours on maintenance so you can focus on moving material vs replacing liners.

Loadout Benefits

Our solutions cover your total loadout requirement irrespective of method.

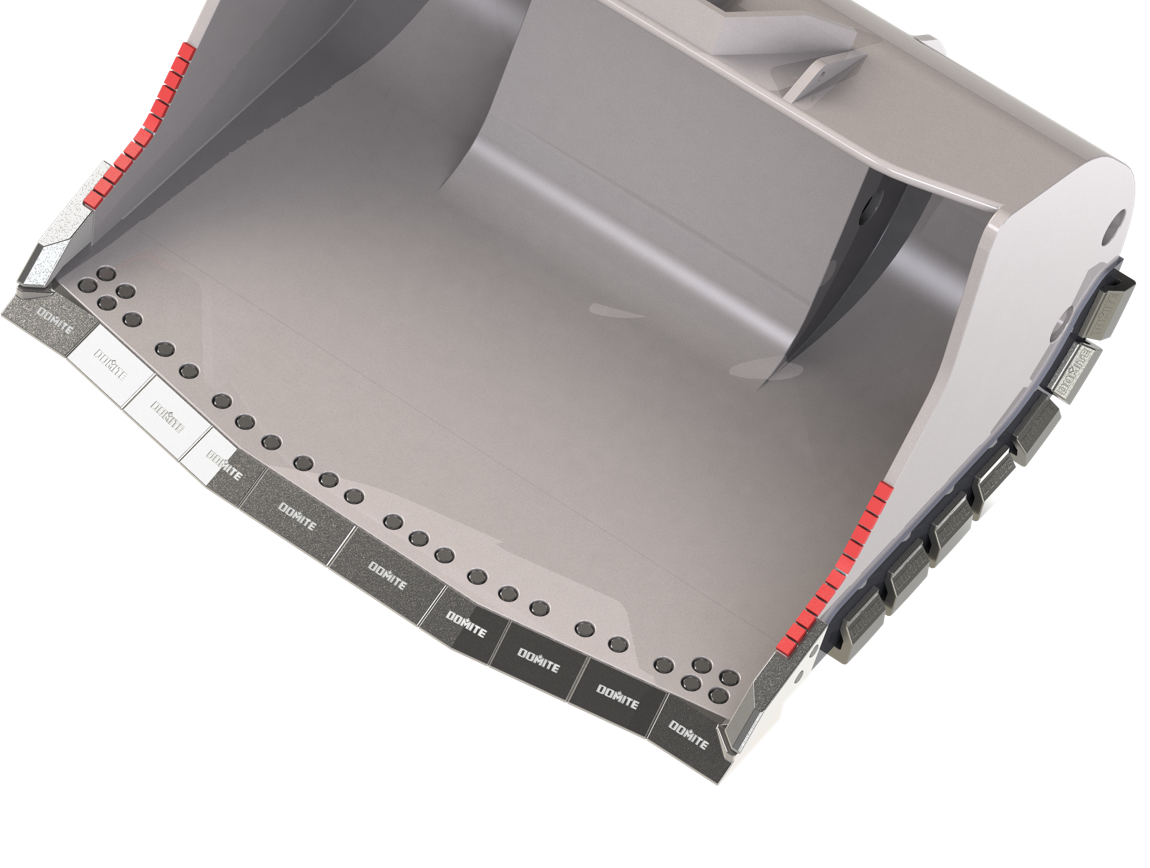

- The modular nature of liners ensures easy handling.

- Reduced change out frequency, less maintenance.

- Reduced material spillage as the liners maintain there form for longer.

- Reduce hang ups & maintain consistent flow with our low coefficient of friction liners

- The modular nature of our liners ensures they can be handled with ease, this also limits unique parts reducing unique part inventory.

Commonly lined areas are:

- Bin throat insert – Lip liners are the top and side liners

- Press frame control gate – Side walls and Arc gate

- Vibratory feeder – Pans, Side walls, feed and discharge

DOMITE® creates custom shapes and sizes specifically designed for your application.

Custom Parts