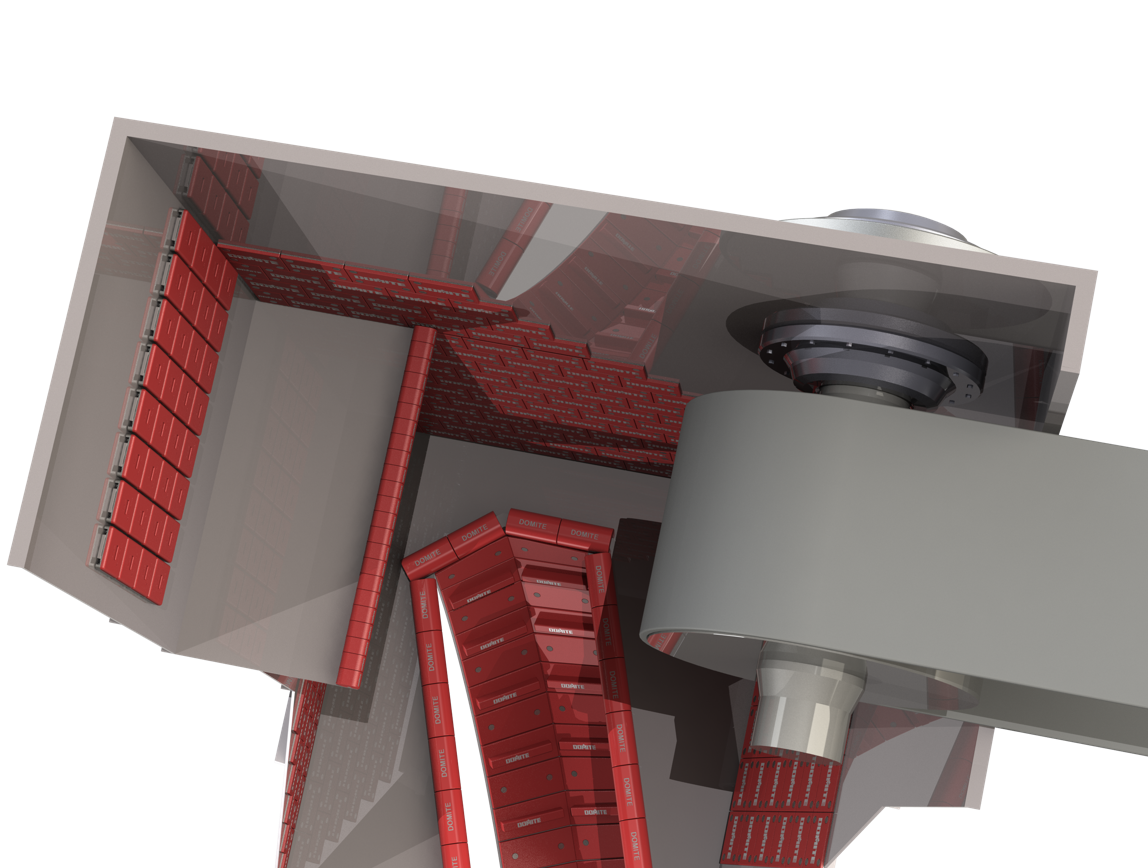

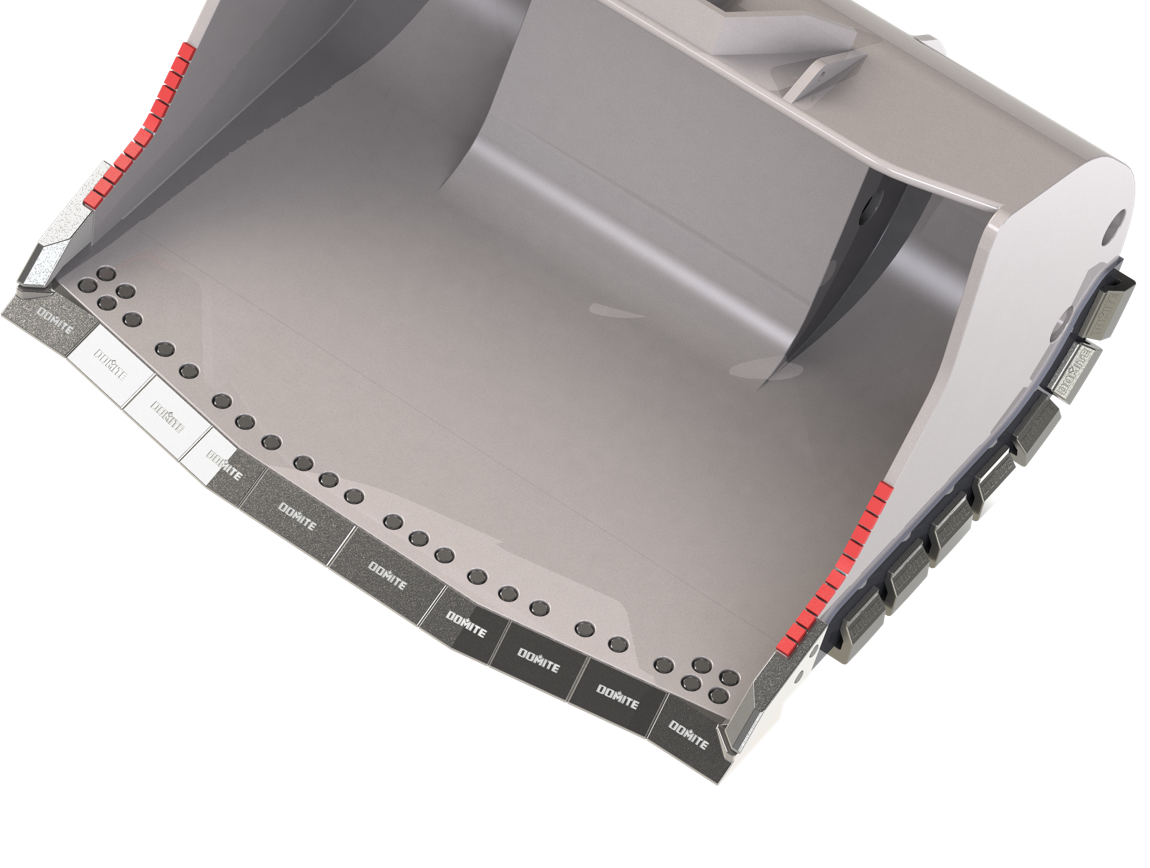

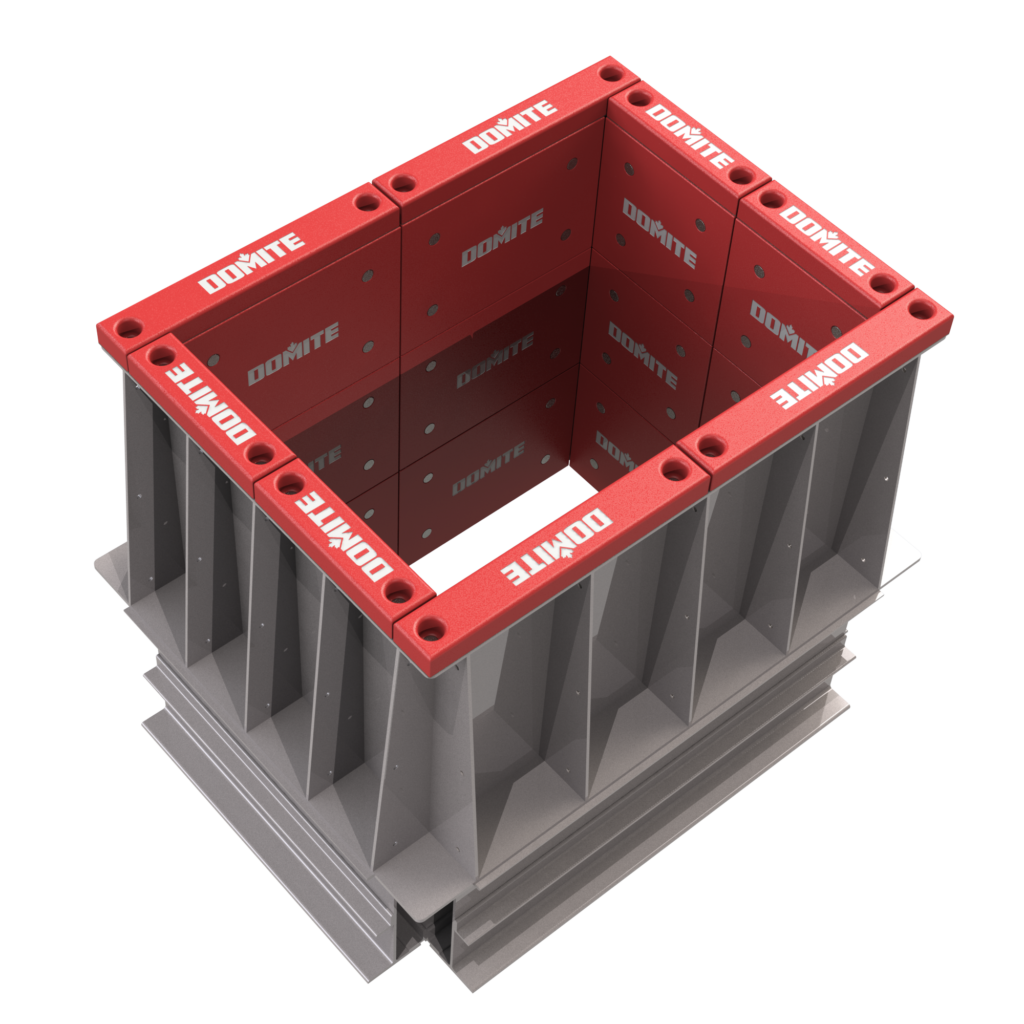

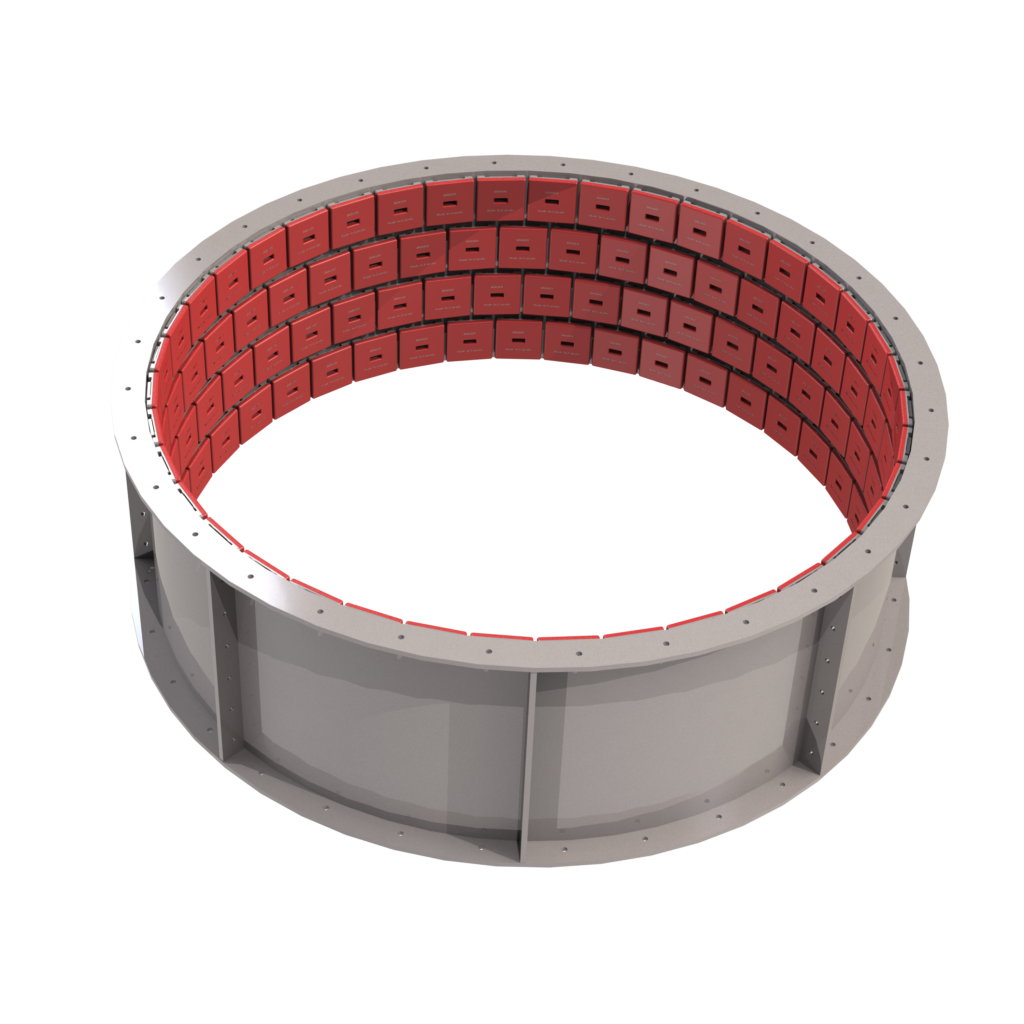

Domite have a range of liner solutions for both flow-through and full ore pass systems. Our superior impact and abrasion resistant alloys will substantially decrease your change out frequency vs common AR plate and overlay products creating a safer, more efficient and lower cost of ownership ore pass. Many of our solutions don’t require hot works so limit the confined space tickets required for change out.

One sided attachment is no problem, we have multiple options available for liner install.

- Mechanical – The Domite Grav Lock is a mechanical liner that doesn’t need access to the back to allow for install of the liners. Grav Locks include wear indicators so you know when to change out the liners before wearing through into the weld base plate.

- Bolt-in – 2x bolt in liner options are available that don’t need access to the back from

- there is the classic nut box option for conventional bolt in liners

- or liners can be bolted to our weld in rail

- Weld-in – if required liners can be plug welded from the front to the sub straight & then the holes filled with an appropriate material to create an even wear face.

Ore Pass Protection Benefits

Domite alloys have a low coefficient of frictions reducing the likely hood of hang up on the liner. The high chrome content reduces oxidation of the liners creating a sticking point.

We realize how important wear monitoring can be so have developed a range of simple wear indicators to easily determine the life left in them before they need to be changed out. This ensures you get the most out of your liners and can accurately forecast change out in your PM.

Domite liners are suited to work with both the Descender systems and loading chute systems.

Related Products

- Grav lock

- Wear indicators

- Bolt in liners