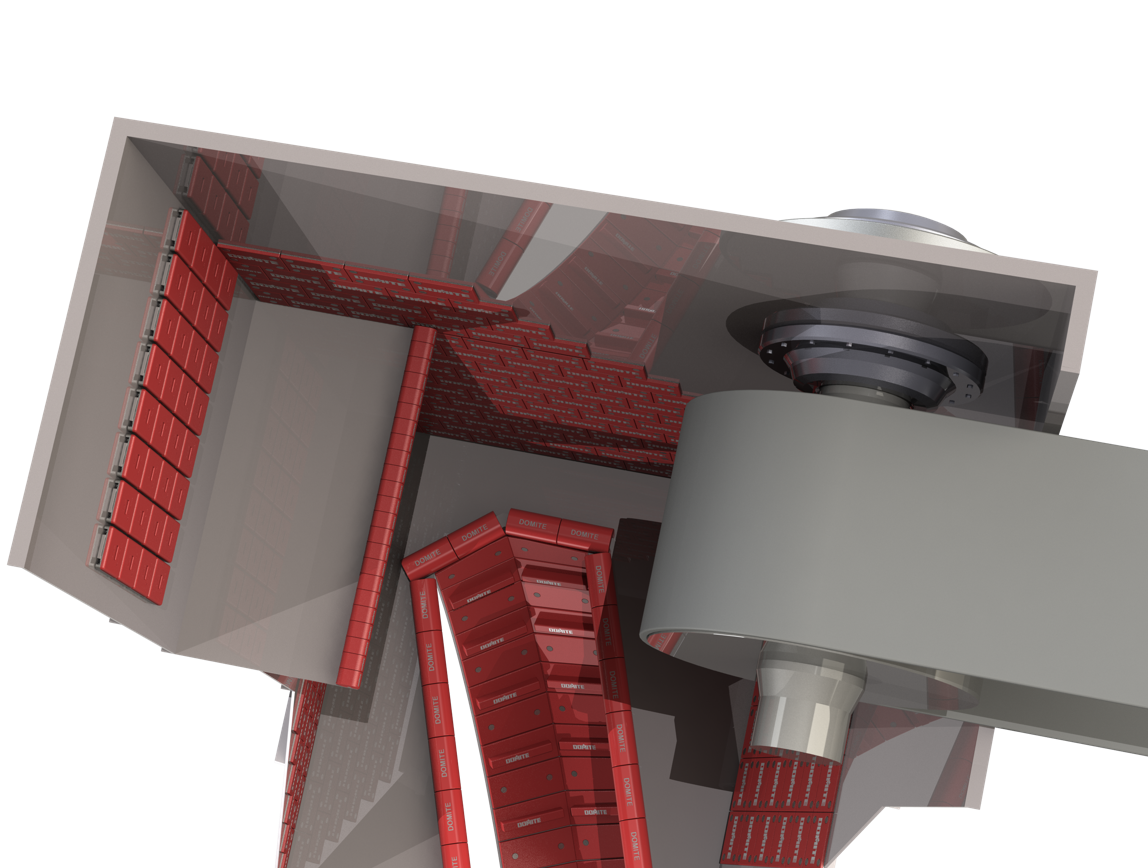

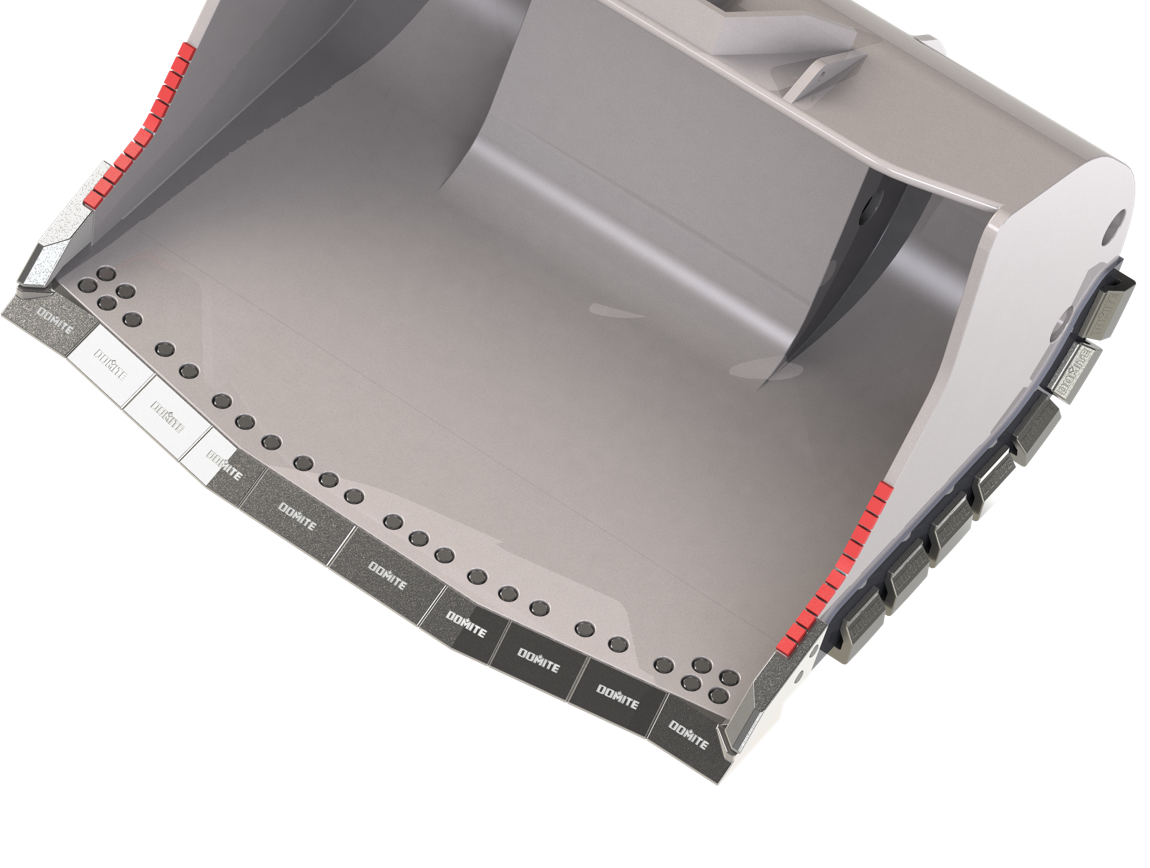

Domite make a range of skirting liners to suit all types of applications feeders, chutes and conveyors. There high wear resistance and customization to site requirements ensure the offer high wear resistance offers prolonged life, reducing maintenance change outs, spillage and dust extraction.

Skirting is primarily used at the receiving and discharge points, notably higher wear is seen at the discharge / load out point. There are many options available depending on your unique set up.

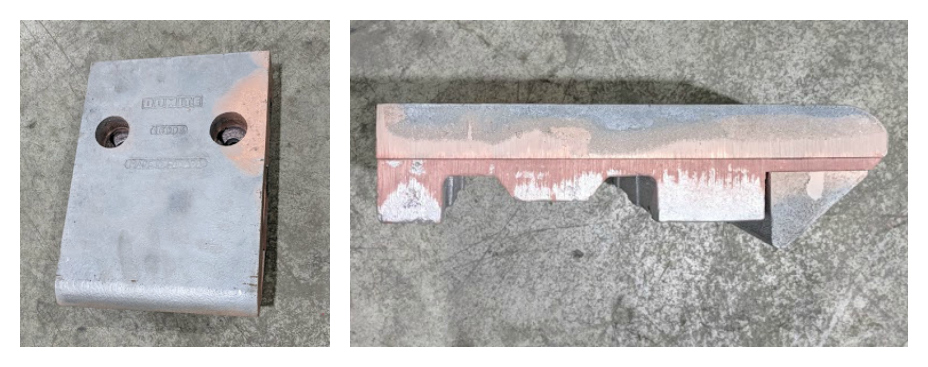

- Cast only liners where there is minimal impact but high abrasion, we offer this in a eco line which has a 40% weight reduction.

- Laminated liners to combat extreme impact and wear. This option allows you the use of studs

- For high wear areas exhibit severe wear we can increase material thickness and or impregnate our liners with sintered tungsten carbide to provide greater resistance.

- Area exhibiting less wear we can offer a hybrid of Domite and a combination of rubber or AR plate lowering your cost of ownership but not compromising on wear resistance you demand.

All options we can include custom tapers to suite the angle of your conveyor, this helps minimize dust emissions and spillage. Not to mention certain designs allow you to flip the liner 180 degrees to maximize liner life.

Talk to us more about our mechanical liners allowing one sided attachment or adjustable skirting liner that you can reduce the height incrementally as the bottom of the liner wears.