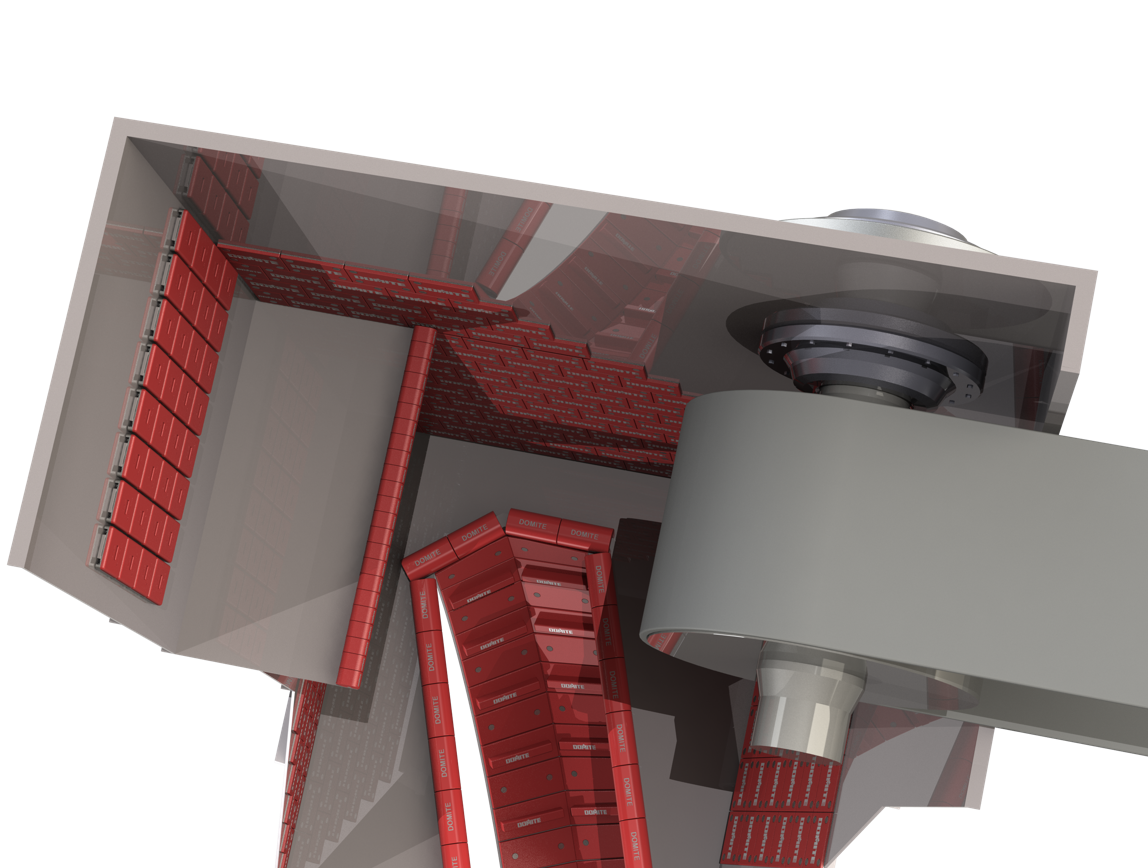

Domite offer superior abrasion resistant pan liners for OEM Vibratory feeders. We have a long history making these and constantly get superior results to AR plate, Cast manganese & overlay pan liners.

Our liners are best suited to high tonnage 247 operations that see severe wear. The Domite material has a very minimal weight differential to steel so there would be little increased weight on the feeder from our Liners. Typical liner thickness is ½” to 1”.

Domite offer these as laminated or rubber bonded liners. Both have excellent wear resistance and impact benefits. If you are concerned about noise levels in your plant the rubber bonded liners offer effective noise suppression of up to 13dbA. They also reduces the vibration transmitted to the supporting structure.

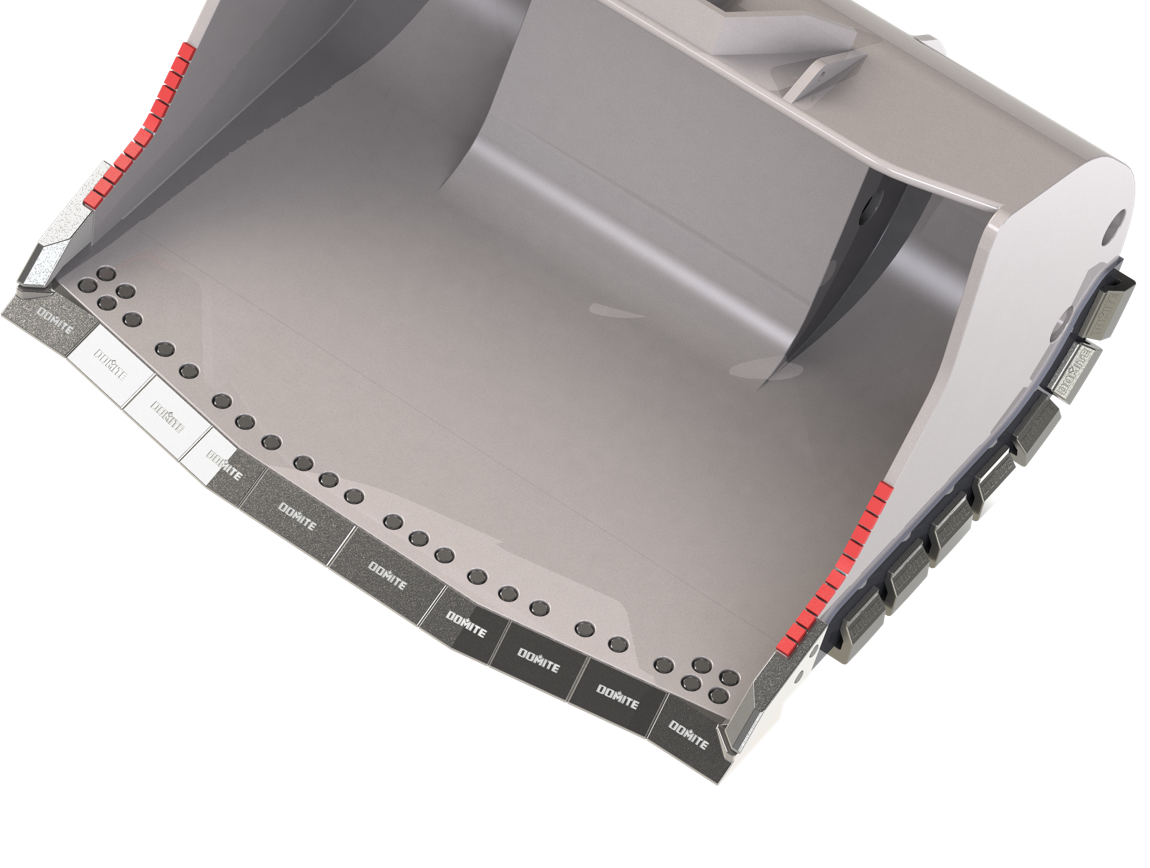

To complement our Liners, we offer Domite bolts. Domite bolts ensure no hardware is exposed to wear as material passes overtop. Due to this they virtually eliminate channeling & premature wear of liners arising when hardware is left exposed.

Our Domite alloys have a low coefficient of friction propagating consistent continuous flow even with wet or sticky materials.

Have a hot link to related case studies

Vibrating Grizzly Feeder

To complement our pan liners Domite make grizzly caps that can be welded to the grizzly. The cast Domite caps have taper profiles (unlike what’s available on CCO or plate alternatives) this special tapered design ensures efficient scalping as material transitions down the grizzly feeder, but also reduces the tendency for material hang-up so are self cleaning.

Different widths thicknesses and lengths are available to suit your application. As these are caps you won’t be replacing the entire grizzly just the cap on top saving costly full replacements when only the tops are typically worn.